Entri yang Diunggulkan

- Get link

- X

- Other Apps

Advertentie Bekijk de autos van Toyota. 3 Core Principles Of Toyota Production System Paperback.

The Toyota Production System House Download Scientific Diagram

The Toyota Production System House Download Scientific Diagram

In addition Hino operates a service parts depot in Mira Loma which distributes parts for Hino brand trucks in Latin American and Caribbean markets.

Toyota manufacturing process. Toyotas Environmentally-Friendly Manufacturing Process Toyota operates under a global earth charter that promotes environmental responsibility throughout the entire company. Toyota Production System basics - Just in time manufacturing lean kaizen jidoka and preventative maintenance - the basis of Toyotas success Process Improvement Japan Australia Click here for the Japanese version. Toyota Production System Documentary - Toyota Manufacturing Production and Assembly at Toyota FactorySUBSCRIBE.

Lean manufacturing or lean production is a production method derived from Toyotas 1930 operating model The Toyota Way Toyota Production System TPSThe term Lean was coined in 1988 by John Krafcik and defined in 1996 by James Womack and Daniel Jones to consist of five key principles. Toyota New Manufacturing Process. Advertentie Bekijk de autos van Toyota.

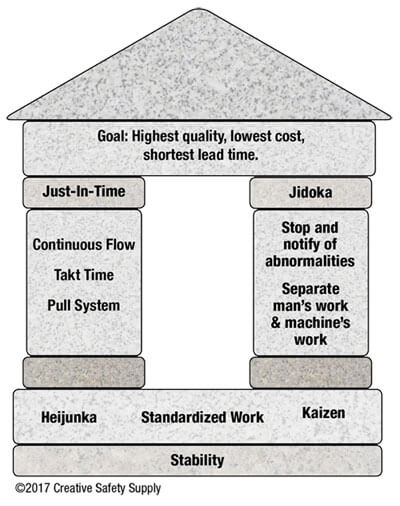

An introduction to the Toyota Production System TPS The Toyota Production system is a major precursor of Lean Manufacturing. Toyota Lean Manufacturing Business Philosophies Toyota lean manufacturing production system has 13 core pillars that guide them in their decisions and continuous improvement. Founded on the conceptual pillars of Just-in-time and Jidoka or Automation with a Human Touch the system was first built off the approach created by the founder of Toyota Sakichi Toyoda and his son Kiichiro Toyoda.

Toyota Material Handling TMH is responsible for manufacturing the majority of Toyota. Toyota Car Manufacturing Process. Workers are central to the whole process and treated as a precious resource for the business.

Toyota Car Manufacturing Process. Precisely specify value by specific product identify the value. Its changed the way the world makes.

Always a Better Way. Toyota is growing and leading the future of mobility through innovative high-quality solutions designed to enhance lives and delight those we serve. One of these core pillars is actually a tool rather than a philosophy.

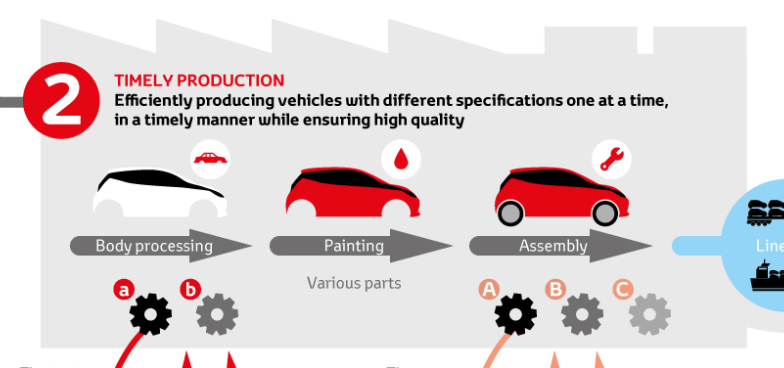

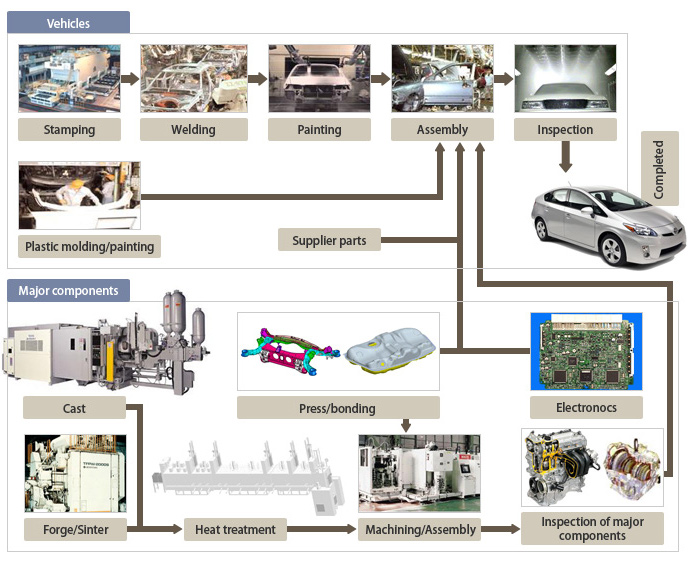

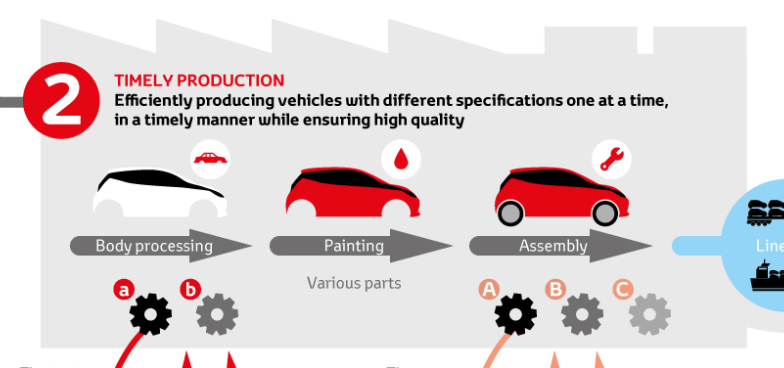

3 Core Principles Of Toyota Production System. The Toyota Production System TPS is an integrated socio-technical system developed by Toyota automotive manufacturer to efficiently organize manufacturing and logistics including the interaction with suppliers and customers to minimize cost and waste. Production Process 3 Painting The welded body is washed and then given an undercoat middle coat and top coat of paint to produce a high-quality painted finish.

Toyota employees exempt staff in human resources accounting engineering safety and production control to. Always a Better Way. Hino Motors Manufacturing USA Inc a consolidated subsidiary of Toyota operates a parts manufacturing plant in Ontario which produces axle components for certain Toyota vehicles.

The Japanese Car Company is a corporate behemoth - but its done much more than just give us Corollas or Land Cruisers.

The Core Principles Of The Toyota Production System 37 Download Scientific Diagram

The Core Principles Of The Toyota Production System 37 Download Scientific Diagram

The Toyota Production System Works For Relationships Too

The Toyota Production System Works For Relationships Too

Toyota Motor Corporation Global Website 75 Years Of Toyota Production Engineering Summary Awards

Toyota Motor Corporation Global Website 75 Years Of Toyota Production Engineering Summary Awards

Tps Toyota Production System Training Strategy Associates

Tps Toyota Production System Training Strategy Associates

The Toyota Production System Tps Kanban Zone

The Toyota Production System Tps Kanban Zone

The Story Of Toyota Part 5 8 Owning The Entire Process The Supply Chain Lean Lessons

An Introduction To The Toyota Production System And Principles

An Introduction To The Toyota Production System And Principles

Toyota Production System Lean Manufacturing And Six Sigma Definitions

Toyota Production System Lean Manufacturing And Six Sigma Definitions

Toyota Production System Tps Lean Manufacturing Creative Safety Supply

Toyota Production System Tps Lean Manufacturing Creative Safety Supply

The Toyota Production System House 5stoday

The Toyota Production System House 5stoday

![]() Toyota Production System In The Lean Lexicon C

Toyota Production System In The Lean Lexicon C

Toyota Production System Tps Lean Manufacturing Creative Safety Supply

Toyota Production System Tps Lean Manufacturing Creative Safety Supply

Comments

Post a Comment